Automatic Dryer CEN

delicately dry your products - increased performances and save loading and unloading time

Automatic Dryer CEN

delicately dry your products - increased performances and save loading and unloading time

download pdf

download pdf

Drying

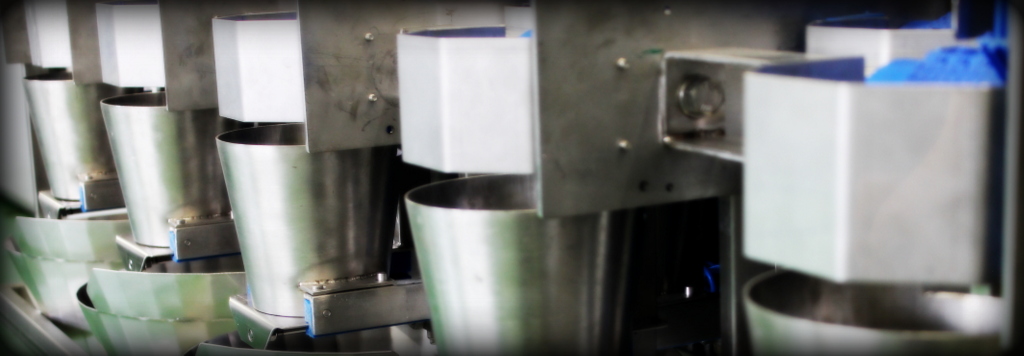

Automatic Dryer CEN

full automatic dryer with loading from top and specific for leafy products, vegetables and brine products

Operating principle

This revolutionary new centrifuge design concept delivers the ultimate control for the drying of delicate salad leaves, standard lettuce varieties, prepared vegetables and delicate herbs.

The product to be dried is delivered into the drum from the top during its slow revolution sequence. This infeed system ensures the minimal movement of the product as it is layered equally over the whole circumference of the centrifuge drum. On completion of the filling cycle the drum accelerates to the pre-set optimal rotating speed to suit the specific product to be dried, when the timed spin cycle, which is also variable in conjunction with the rotational speed is completed the drum automatically slows down and the product very gently is unloaded from the bottom.

The drum does not overturns during loading and unloading step. During the unloading part of the production cycle the centrifuge drum turns very slowly and activates a high pressure air knife which cleans all residual particles of leaf out of the drum. The continuous production cycle immediately continues without interruption and the infeed charge conveyor re-fills the drum. The unique construction of the centrifuge minimizes product damage because of the spacious drum dimension and the controlled layer thickness of the product which eliminates product pressure during the spin cycle.The drum has a completely smooth inner surface without contact parts which could directly damage the product.

The centrifuge can be supplied in 4 dimensions .

Electrical panel IP65, low voltage controls. CE marked.

Optional: Automatic Charging Belt Conveyor

The product to be dried is delivered into the drum from the top during its slow revolution sequence. This infeed system ensures the minimal movement of the product as it is layered equally over the whole circumference of the centrifuge drum. On completion of the filling cycle the drum accelerates to the pre-set optimal rotating speed to suit the specific product to be dried, when the timed spin cycle, which is also variable in conjunction with the rotational speed is completed the drum automatically slows down and the product very gently is unloaded from the bottom.

The drum does not overturns during loading and unloading step. During the unloading part of the production cycle the centrifuge drum turns very slowly and activates a high pressure air knife which cleans all residual particles of leaf out of the drum. The continuous production cycle immediately continues without interruption and the infeed charge conveyor re-fills the drum. The unique construction of the centrifuge minimizes product damage because of the spacious drum dimension and the controlled layer thickness of the product which eliminates product pressure during the spin cycle.The drum has a completely smooth inner surface without contact parts which could directly damage the product.

The centrifuge can be supplied in 4 dimensions .

Electrical panel IP65, low voltage controls. CE marked.

Optional: Automatic Charging Belt Conveyor

Features

Top loading and unloading from the bottom

> No tipping of the drum in the loading and unloading

> Low maintenance

> Very easy to clean

> No tipping of the drum in the loading and unloading

> Low maintenance

> Very easy to clean

Product specification

The automatic dryer CEN is suitable for drying of all the products in leaf, products in brine and processed vegetables

Capacity

The capacity of the dryer is entirely dependent on the type of product, the water retention of the product, and the level of dryness required. Centrifuges are available up to 1500 Kg / h

Options

Accessory: Tape loading vibrating

download pdf

download pdf PULSE

PULSE FRUIT

FRUIT

PINEAPPLE

PINEAPPLE KIWI

KIWI MANGO

MANGO MELONS

MELONS ONIONS

ONIONS ERBE AROMATICHE

ERBE AROMATICHE OTHER

OTHER TRANSPORTING

TRANSPORTING