Multiproduct weighter – Fresh Produce Mix Mode

Weighter for products that have to be mixed after weighting such as fruit salad or frozen mix

Operating principle

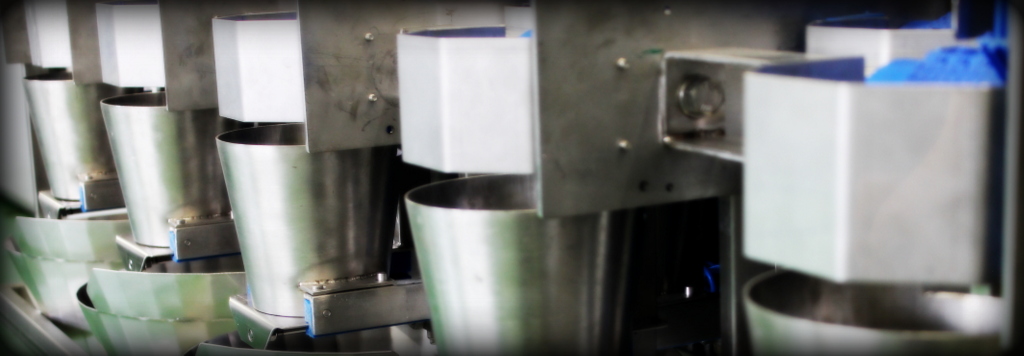

GFT's fresh food weigher, presented at Fruitlogistica Berlin 2013 is a innovative system to weight fresh and sticky products and to weight ingredients that have to be mixed with precise percentuages. The weighter is able to automate the weighting process that before was possible only manually. The equipment reduce up to 5 time the labour cost, increasing speed , accuracy and hygene. Especially designed for the fruits and vegetable, seafood, dairy and frozen food industry. MIXED MODE This machinery allow to manage different ingredients and mix them directly in the final packaging.

It's particularly indicated in case of Fresh and Sticky products such as Fruit salad , Seafoods, Frozen Food. Each ingredient is loaded in a separate hopper. Each hopper feeds 2 conveyors that delicately move the ingredient toward 2 different weighing system. There are 10 weighing station in total. The special Cross Flights design of the conveyor allow to move one piece by one and have not damages for the product during transport , preserving the shelf life of the ingredients. Once the target weigh is reached the ingredients will be unloaded directly in the packaging (glass, cup, bucket, punnet).

The packagings are filled with the exact product percentage for each ingredient.

Capacity: up to 15 mixed ingredients beats per minute.

ONE INGREDIENT MODE In case of one single ingredient product the weighing system increase the capacity up to 40-60 beats per minute. Options: Automatic Loading / Adaptor for multi-packaging

It's particularly indicated in case of Fresh and Sticky products such as Fruit salad , Seafoods, Frozen Food. Each ingredient is loaded in a separate hopper. Each hopper feeds 2 conveyors that delicately move the ingredient toward 2 different weighing system. There are 10 weighing station in total. The special Cross Flights design of the conveyor allow to move one piece by one and have not damages for the product during transport , preserving the shelf life of the ingredients. Once the target weigh is reached the ingredients will be unloaded directly in the packaging (glass, cup, bucket, punnet).

The packagings are filled with the exact product percentage for each ingredient.

Capacity: up to 15 mixed ingredients beats per minute.

ONE INGREDIENT MODE In case of one single ingredient product the weighing system increase the capacity up to 40-60 beats per minute. Options: Automatic Loading / Adaptor for multi-packaging

Features

> Labour cost reduction

> High Hygene standards

> Easy to clean

> Versatile

> High Hygene standards

> Easy to clean

> Versatile

Product specification

The weighter is suitable for weighting fresh cut produce, fresh fruit, dryed fruits, frozen products, dairy products

Capacity

The capacity of the weighter is entirely dependent on the type of product, the weight of the packaging and on the numbers og ingredients. Is possible to reach up to 600 pieces per minute

Options

Accessory: Automatic Loader

download pdf

download pdf download pdf

download pdf PULSE

PULSE

POTATOES

POTATOES VEGETABLES

VEGETABLES CELERIAC

CELERIAC CHICORY

CHICORY BABY LEAF

BABY LEAF BELL PEPPERS

BELL PEPPERS ONIONS

ONIONS SEDANO

SEDANO EGGPLANTS

EGGPLANTS ZUCCHINI

ZUCCHINI LEEKS

LEEKS CABBAGE

CABBAGE ERBE AROMATICHE

ERBE AROMATICHE CARROTS

CARROTS OTHER

OTHER TRANSPORTING

TRANSPORTING